- Home

- Our Company

- Latest News

- Infrared LEDs (IR LEDs): How They Work, Key Applications, and Selection Guide

Infrared LEDs (IR LEDs): How They Work, Key Applications, and Selection Guide

Infrared LEDs (IR LEDs): A Complete Guide

Infrared (IR) technology surrounds us in ways we rarely notice. From the remote control on your coffee table to biometric scanners at airports, wearable health devices on your wrist, and even the smoke detectors in your home, infrared LEDs (IR LEDs) quietly power some of the world’s most important technologies.

As devices become smaller, smarter, and more connected, IR LEDs have become one of the most widely used optoelectronic components. This guide answers the most common questions about IR LEDs — what they are, how they work, and where they’re used — with extra insights into receivers, smoke detection, photo-interrupters, and even how they measure your heartbeat.

How do IR LEDs work?

IR LEDs operate like visible LEDs: current passes through a semiconductor junction and releases photons. Here, photons fall in the infrared range, which is invisible to human eyes but ideal for sensing and communication. Optical output depends on wavelength, optics/beam angle, drive current, pulse width, and thermal design.

What is an Infrared LED?

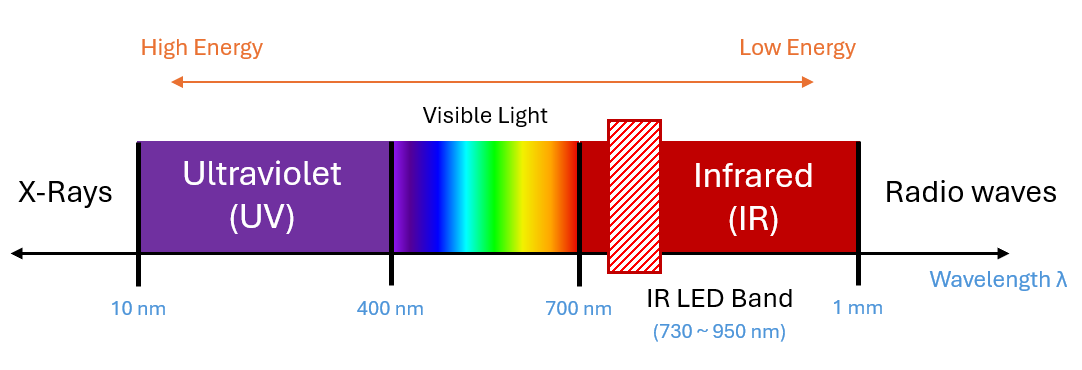

An infrared LED (IR LED) is a semiconductor device that emits light in the infrared spectrum, typically between 700 nanometers and 1 millimeter in wavelength.

Although invisible to the human eye, this light is easily detected by sensors and cameras, making IR LEDs ideal for invisible illumination, proximity sensing, and wireless communication.

Most designs use near-infrared wavelengths such as 850 nm or 940 nm, selected according to the detector’s sensitivity and the application’s requirements — for example, 850 nm is often preferred for camera systems, while 940 nm provides completely invisible operation for consumer and biometric devices.

What wavelengths are common in IR LEDs?

Popular peaks include 850 nm (camera-friendly, faint red glow) and 940 nm (no visible glow). Specialized wavelengths such as 730 nm or 760 nm address machine vision and niche sensors.

850 nm vs 940 nm: which should I choose?

- 850 nm: peak sensitivity for most image sensors; best range/clarity for CCTV, DMS/OMS, doorbells, and drones (may show faint red glow at high current).

- 940 nm: “no-glow” UX for biometrics and consumer devices; ideal when user-visible glow is undesirable (slightly lower camera sensitivity).

- Optics: narrow beams increase range; wider beams improve uniformity. External lenses and arrays tailor the pattern.

Browse our IR LEDs or request custom wavelengths and optics.

IR LED vs IR Sensor: what’s the difference?

| Aspect | IR LED (Emitter) | IR Sensor (Receiver/System) |

|---|---|---|

| Function | Emits IR light | Detects IR radiation |

| Typical parts | LED die/package | Photodiode, phototransistor, or IR receiver module |

| Use cases | Illumination, signaling, communication | Motion, proximity, remote reception |

| Selection keys | Wavelength, beam, optical power, package | Sensitivity, bandwidth, ambient-light immunity |

Need emitter/receiver pairing help? Contact us for custom wavelength and optics tuning.

What are the different types of receivers?

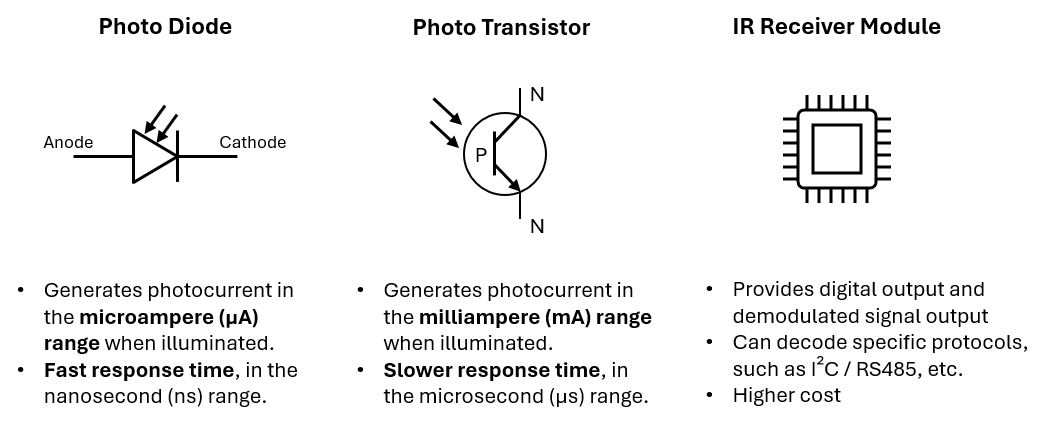

IR systems pair an emitter (IR LED) with a receiver. The main receiver options are:

- Photodiode (PD): very fast (ns), small signal — best for high-speed sensing.

- Phototransistor (PT): slower (µs) but stronger signal — good general-purpose detector.

- IR receiver module (IRM): detector plus demodulation IC (e.g., 36–56 kHz for remotes) providing a clean digital output.

Why modulate at 38–56 kHz? Modulation lets IR receiver modules reject ambient sunlight and electrical noise, improving range and stability.

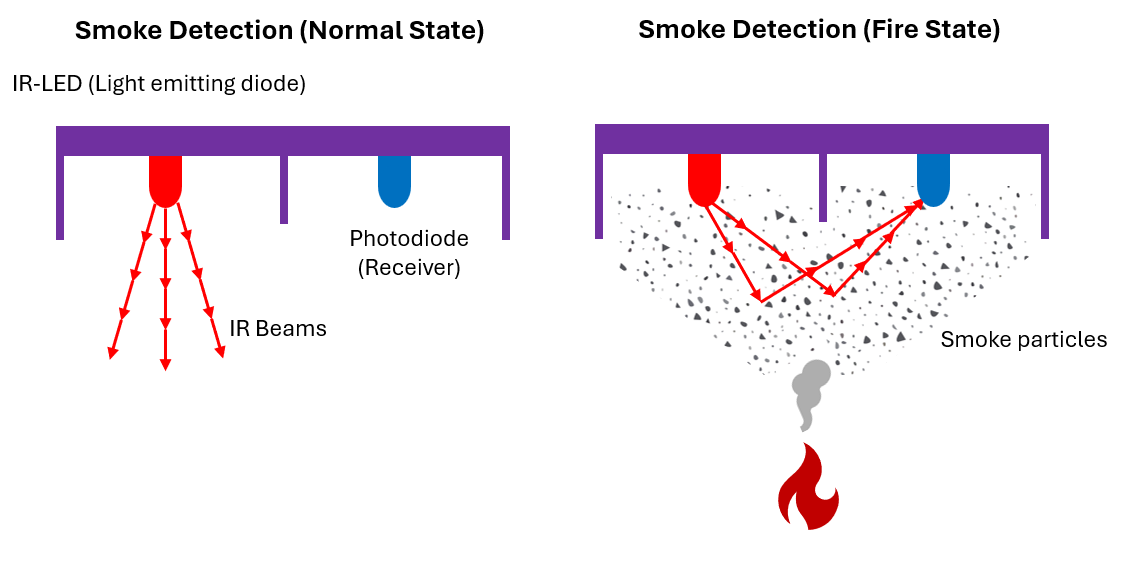

How does infrared smoke detection work?

An IR LED emits into a detection chamber. In clean air, the receiver sees little to no light. When smoke particles appear, they scatter the IR toward the receiver (PD or PT), creating a measurable change that sets off the alarm.

This optical principle enables early detection in residential, commercial, and industrial systems.

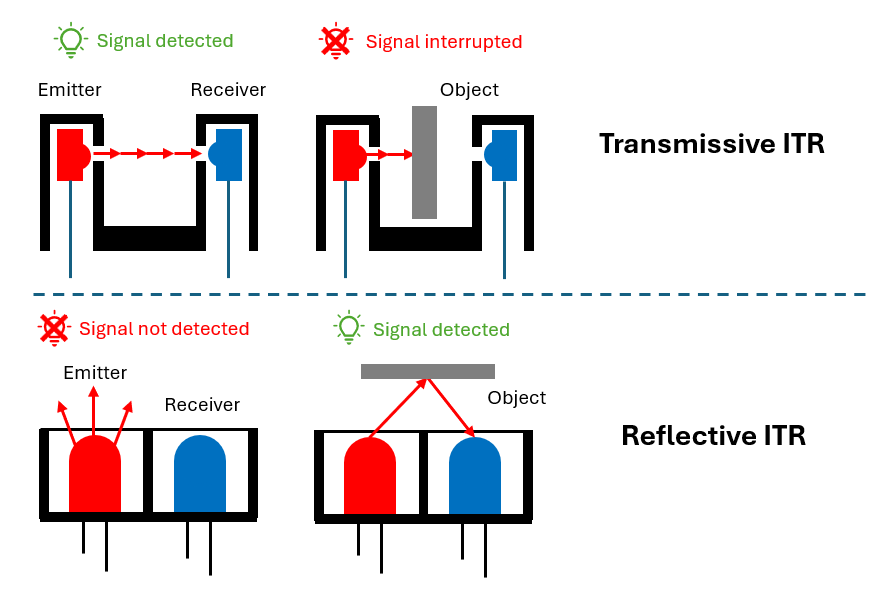

What are Photo-Interrupters (ITRs)?

ITRs are compact opto-switches combining an IR emitter and a receiver. Two common types:

- Transmissive (slot type): emitter and receiver face each other across a gap; an object breaking the beam changes the output (e.g., paper feed in printers, rotary sensing).

- Reflective: emitter and receiver sit side-by-side; a nearby surface reflects IR back to the receiver (e.g., knob/edge detection in appliances and robots).

How do IR LEDs measure heart rate and blood oxygen?

Smart wearables use IR together with red and green LEDs to measure health data. Heart rate (PPG method) is detected as blood pulses change absorption levels. Blood oxygen (SpO₂) is calculated by comparing red vs. infrared absorption, since oxygen-rich and oxygen-poor blood absorb light differently.

IR LED pinout & driving basics

- Polarity: through-hole parts use long lead = anode, short lead/flat edge = cathode; SMD packages mark the cathode.

- Forward voltage: typically ~1.2–1.5 V (varies by part); drive with a series resistor or constant-current driver.

- Pulsed drive: using duty cycle raises peak optical power without overheating (observe absolute ratings).

- Eye safety: manage current, distance, and exposure; narrow beams need particular care.

Why use IR light instead of visible light?

- Invisible to users — discreet for sensing and surveillance.

- Low power — friendly to battery devices.

- Performs in low light — cameras see what people can’t.

- Eye-safe compared to narrow laser beams.

What about “no-red-exposure” IR LEDs?

Standard 850 nm devices can show a faint red glow. No-red-exposure designs minimize visible emission — preferred for covert surveillance, biometrics, and baby monitors.

Why do some applications need high-power IR LEDs?

High-power IR LEDs act as invisible “fill lights” so cameras capture clearer images in low light. They are widely used in security cameras, driver/occupant monitoring, smart doorbells, and drones.

Applications at a glance

- Security & Vision: CCTV, video doorbells, drones (invisible fill light).

- Biometrics & Consumer: face unlock, eye tracking, wearables (940 nm for no-glow UX).

- Automation & Robotics: photo-interrupters, reflective sensors, counters.

- Building Safety: smoke and flame detection.

- Remotes & Control: 38–56 kHz modulated IR links.

Choosing an IR LED (quick checklist)

- Wavelength: 850 vs 940 nm (or specialty peaks)

- Beam angle & optics: range vs uniformity; consider lenses/arrays

- Optical power: continuous vs pulsed operation

- Package: SMD size, through-hole, or high-power packages

- Receiver pairing: PD/PT/IRM, filters, and modulation

- Thermal & safety: heatsinking, duty cycle, eye-safety

Learn more

At Lumex, we offer standard and customized IR solutions — wavelength, beam angle, output power, and packaging — to fit your application. Explore the series: Lumex Infrared LED Series. For custom designs, visit Contact Us; for purchasing and availability, see Where to Buy.