- Home

- Our Company

- Latest News

- Lumex Launches PIP (Pin-In-Paste) Series: Reflow-Capable Through-Hole LED Indicators

Lumex Launches PIP (Pin-In-Paste) Series: Reflow-Capable Through-Hole LED Indicators

Lumex PIP Series: Reflow-Capable LED Indicators for Simplified Manufacturing

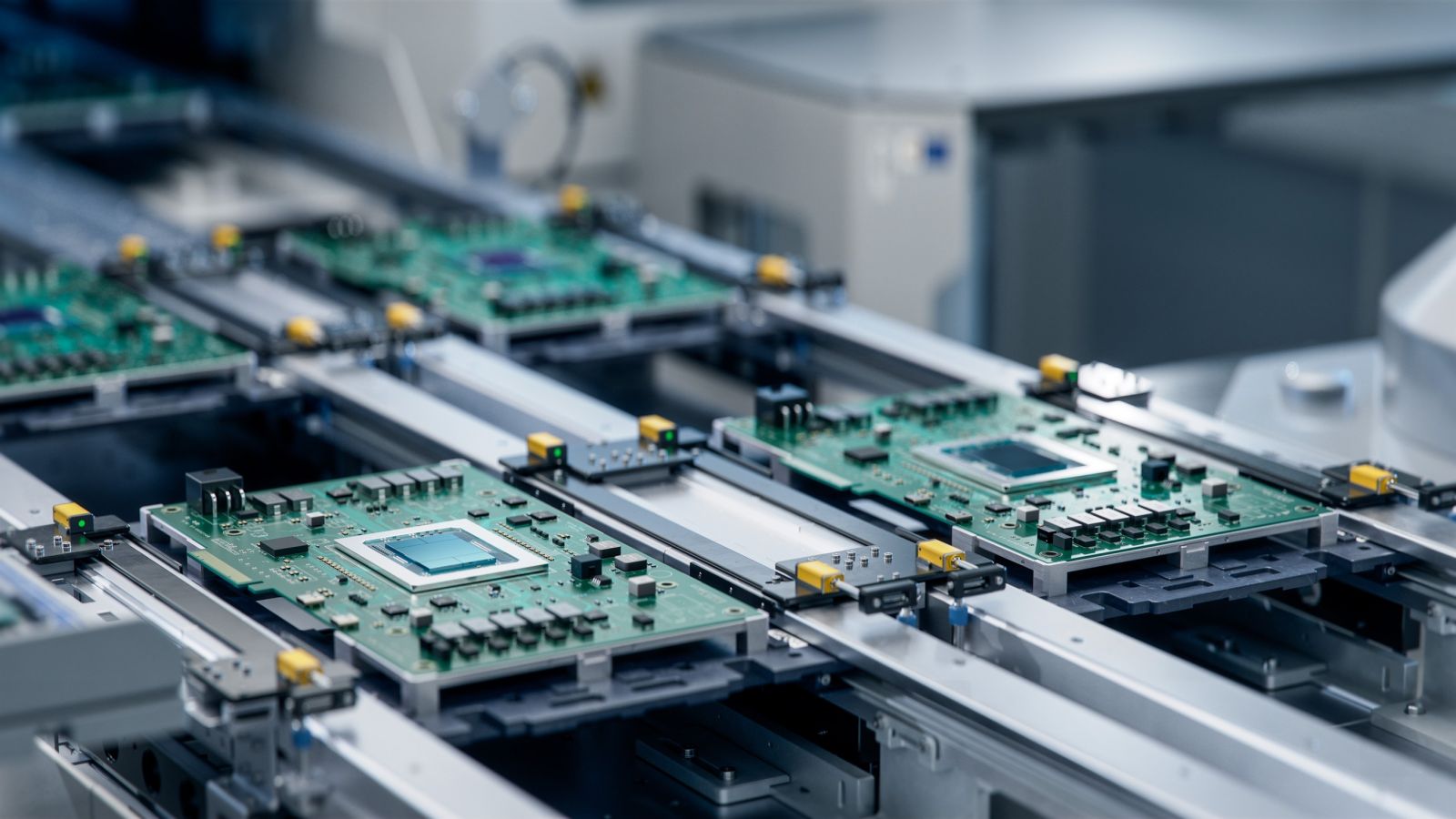

In today’s fast-paced electronics industry, design engineers and purchasing managers are constantly on the lookout for components that can withstand demanding manufacturing processes and harsh environmental conditions—without driving up costs. Lumex’s newly launched PIP (Pin-In-Paste) series delivers on these needs, offering high-temperature performance, simple installation, and an all-in-one LED display solution that eliminates redundant components.

Built for Reflow, Designed for Efficiency

Traditional through-hole LEDs often require a separate wave soldering or manual soldering, increasing production time, labor, and equipment costs. The Lumex PIP series eliminates these extra steps by being fully compatible with reflow soldering and Paste-in-Hole processsing, allowing seamless integration alongside other suface-mount (SMT) components. This innovative approach streamlines manufacturing by:

- Single, Unified Assembly: No need for additional machinery or separate soldering stages.

- Reduced PCB Assembly Steps: Combines wave soldering and reflow into a single, more efficient process.

- Lower Production Costs: Fewer manufacturing stages and shorter assembly times reduce labor and overhead expenses.

- Faster Turnaround: Assemble and solder everything in one pass, improving efficiency and throughput.

Seamless Transition for Existing Through-Hole LED Designs

For manufacturers already using through-hole LEDs in their PCB designs, adopting new components often require redesign efforts. The Lumex PIP Series eliminates this challenge by providing a reflow-capable through-hole LED solution, allowing customers to upgrade their assembly process without altering their PCB layout.

Unlike SMT LEDs, which require different footprint configurations and additional design modifications, the PIP Series maintains the same through-hole structure while being able to withstand high-temperature reflow soldering. This means manufacturers can integrate automated reflow soldering into their production lines without making costly design changes or reworking existing PCB layouts.

Eliminate Redundancy with a Single, Effective Solution

The Lumex PIP series is available in both single-level and 4-level indicators, with offering from single color to YRGB LEDs, catering to various display needs and enabling multiple status indications within a single component while maintaining a compact PCB layout:

- Design Flexibility: Multiple LED levels accommodate different board layouts, form factors, and brightness needs.

- Streamlined Inventory: Fewer discrete parts to manage and reorder, improving efficiency for procurement teams.

A Competitive Edge for Multiple Industries

From industrial instrumentation to consumer-facing electronics and automotive systems, the Lumex PIP series is poised to provide a reliable, versatile, and cost-effective LED solution. With its robust temperature tolerance, simplified manufacturing process, and single-part versatility, this new product line helps customers:

- Ensure Operational Reliability in harsh or warm environments.

- Meet Tight Project Deadlines by streamlining assembly and test cycles.

- Control Production Budgets through reduced component counts and process steps.

With the new Lumex PIP series, manufacturers can confidently tackle the challenges of heat-intensive processes, complex assembly lines, and redundant components. By combining high-temperature endurance, Paste-in-Hole compatibility, and multiple configuration levels into one LED platform, Lumex offers a strategic advantage for those seeking to optimize both performance and cost. Embrace the future of LED manufacturing with Lumex—and discover how these innovative solutions can take the heat for you.